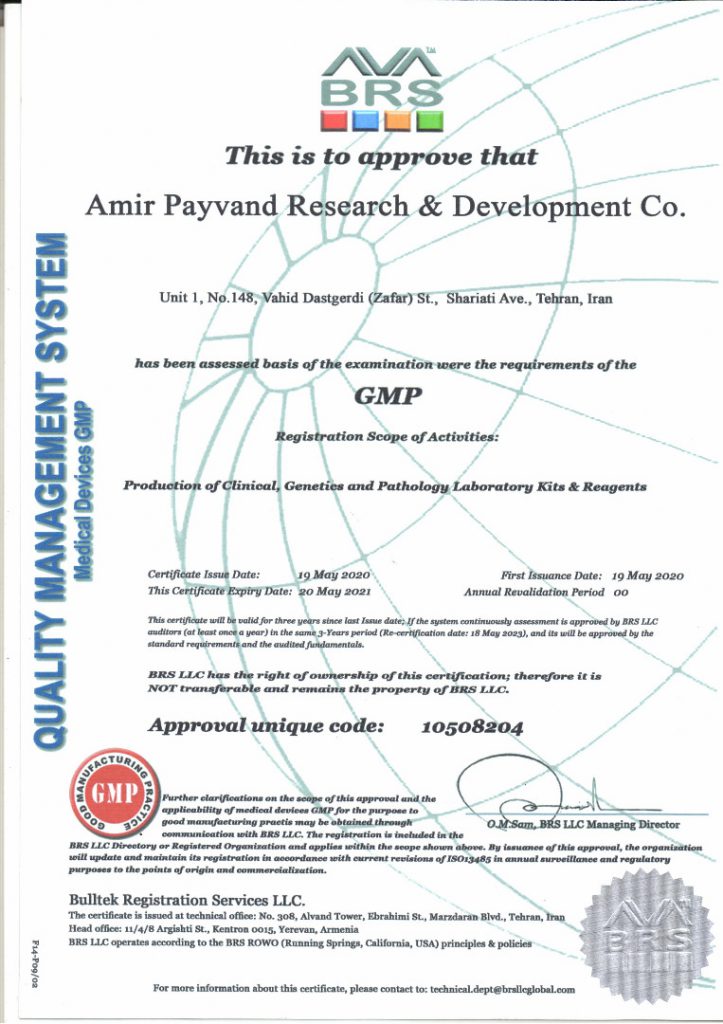

Ensuring the safety and quality of laboratory diagnostic products is of interest to consumers today. In this regard, Amir Payvand Research & Development Company received GMP (Good Manufacturing Practice) certificate for the production of laboratory (clinical, Genetic, molecular and pathological) kits and solutions.

Amir Payvand Research & Development Company has been evaluated by BRS, which is one of the best and most reputable companies in the field of issuing international certificates for production management systems, to receive the appropriate product quality assurance certificate.

GMP is an important step in the quality management system for the production of kits and diagnostic solutions in the medical and laboratory fields, which increases customer confidence in the manufacturer’s commitment to trade and the production of quality products.

Compliance with GMP requirements requires compliance with the minimum quality control guidelines applicable to all production units. Many manufacturing companies have considered obtaining GMP certification for their products as the basis on which to develop quality management systems and their products.

GMP principles are control factors that are not just focused on a specific process, but monitor the entire production and quality control operation and are the basis for producing a healthy product. These principles create and maintain suitable infrastructure for production such as machinery, environment, equipment, work force, etc.

An overview of the main requirements of GMP:

– Definition of all production, systematic, operational and revised processes, so that the capacity and production capacity of the product is proven with quality and in accordance with the predicted specifications.

– Accreditation of sensitive and key stages of production processes and major changes in each process.

– Providing the necessary facilities and equipment such as; Efficient, skilled and trained personnel, desirable building and space, appropriate equipment, quality raw materials, utensils and proper labeling; Appropriate storage and transportation, approved guidelines and instructions

– Develop clear, operational guidelines and instructions, in simple and unambiguous language for the use of tools and equipment and equipment.

– Training production line technicians in such a way that they are ready to perform the processes correctly.

– Preparing the records of the documents during the whole production operation, in such a way that it indicates that all the steps and requirements are performed in accordance with the defined instructions and guidelines and the production of the product with quantitative and qualitative specifications is predicted.

– It is necessary to record and review hazardous activities.

– Keeping documents and records of different stages of production, including complete and traceable documentation of product distribution

– Existence of an efficient system for recalling returned products sold

– Existence of a system for reviewing and investigating received complaints, investigating the cause of quality defects and taking corrective measures and preventing their recurrence.